Insulation

Goals

Our average July and August high temperatures are 69 degrees, and thus cooling is a minor factor in this part of Washington – we typically only air condition a few days per year. Thus, even though the heat pump can either heat or cool, we’ll talk mostly about heating to keep things simple with the understanding that things that reduce heating energy requirements so the same for cooling.

Heat is mostly lost from homes in two ways:

- First, it is conducted through exterior surfaces — floor, walls, ceiling, windows, and doors.

- Second, warm air leaks (or is intentionally blown) outside and is replaced by cool air from outside that must then be heated to room temperature.

All of this lost heat must be replaced to keep the house temperature stable. Thus, the total rate of heat loss on the coldest expected winter day will determine the minimum size of a heating system, as will be discussed further under Equipment.

In this section we will discuss the measures we took to reduce conducted heat loss by using insulation. The Airflow section will cover intentional and accidental exchange of outside air.

Floor

Dirt has some thermal resistance which depends on its composition and moisture level. Many houses have been built with otherwise-uninsulated floors, though current Washington code requires some. These uninsulated slab floors are cool in the winter and colder as you get closer to the outside wall.

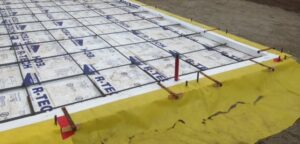

For the Demonstration House, we augmented this natural insulation by creating a “bathtub” consisting of four inches of foam insulation under and around the edges of our floor. Since the insulation must support the weight of the concrete slab and everything on top of it, we used structural Extruded Polystyrene (XPS) foam which has a very high compression rating and an excellent thermal resistance of five per inch of thickness. Adding the R20(see note below) from the foam to the natural resistance of the dirt on which it sits, the estimated average thermal resistance across the floor is approximately R40.

The insulation is very effective. In fact, several visitors who toured the house in their stocking feet thought that we had in-slab heating of some sort. Measured on a cold January day, the temperature of the middle of the floor was just 0.2 degrees below room temperature while near an outside wall it was 1.2 degrees lower.

Rigid foam insulation was not an inexpensive choice, though. Although there is little labor involved, the cost of the insulating material was about $2.00 per square foot, or about $4,000 total for our house. There is also an environmental cost – XPS insulation is rated poor for environmental impact because of the blowing agents used in its manufacture. Improvements are expected in structural insulation, however, so we are hopeful that situation will improve in coming years.

For a detailed discussion of the pros and cons of insulated slab floors, see The Pros and Cons of an Insulated Slab Floor in the Documents section.

Walls

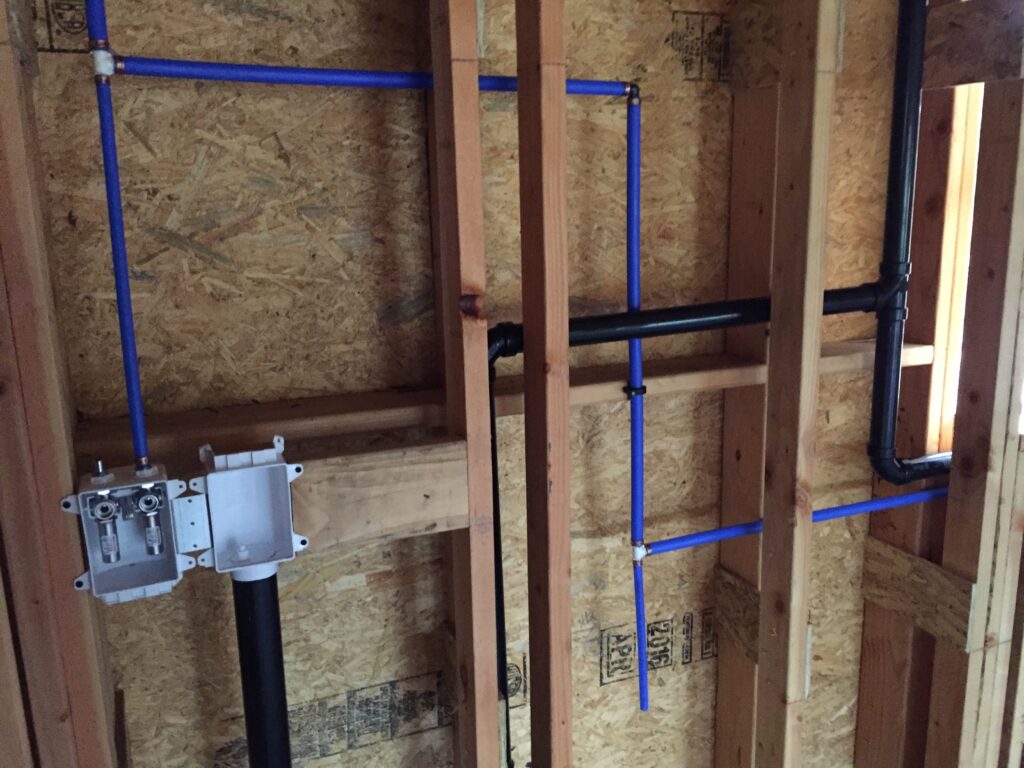

We were also aiming for about R40 heat resistance for our walls. We chose to use “double stud” construction for our house, but there are lots of ways to achieve that goal. In this wall design an outer wall consisting of 2X6 studs spaced 24” apart (and aligned with the roof trusses) supports the siding and the roof. An inner wall of 2X4 studs is spaced 2-1/2” away from the outer wall with its studs offset from the outer wall studs. The inner wall is lightly framed as it serves only to create space for 11-1/2” total thickness of insulation.

The space between the walls significantly reduces the heat flow that would otherwise occur when wooden members extend from inner to outer wall surfaces (as is the case with conventional construction) because wood has a thermal resistance of only 1/inch compared with the insulation’s 4.1/inch.

The space between the walls significantly reduces the heat flow that would otherwise occur when wooden members extend from inner to outer wall surfaces (as is the case with conventional construction) because wood has a thermal resistance of only 1/inch compared with the insulation’s 4.1/inch.

In our design, the space between the walls falls directly over the insulation around the edges of the slab floor, so that the insulating layer around the floor is continuous with the wall insulation preventing “thermal bridging” at that connection point.

Regardless of construction method, high-R walls will be thicker than standard construction and, in fact, are one the few places where the energy efficiency measures are noticeable to a casual observer.

Double-stud walls have the added advantage of reducing wiring and plumbing labor because tradespeople don’t need to drill holes to pass wires and pipes horizontally through the wall.

After the wiring and plumbing (and anything else that goes in the wall) were installed, a fabric was stapled over the inside of the wall and the entire cavity filled with high-density blown-in fiberglass insulation.

The nominal resistance to heat flow (measured through just the insulation) is R48, however the entire wall structure, not counting windows and doors, has an effective thermal resistance of R 37 when the effect of the framing members is included.

The measured temperature of the interior finished wall surface on a cold winter day was just 0.1 degrees below internal air temperature.

Ceiling

Many houses are insulated using loosely blown-in cellulose or fiberglass. This was particularly easy in our case because the hipped trusses (see discussion in Design) provide a two-foot-high wall along the north and south edges, making it easy to blow in enough loose fiberglass material to achieve an R60 thermal barrier (about two feet thick) all the way to the outer wall sheathing.

Adding the additional insulation was not a major cost item – once the insulation company has set up its equipment and personnel to blow in insulation, the incremental cost to increase the thickness is not that great.

Adding the additional insulation was not a major cost item – once the insulation company has set up its equipment and personnel to blow in insulation, the incremental cost to increase the thickness is not that great.

The attic-to-wall insulation interface is essentially continuous with only a thin board between them, minimizing any thermal bridging.

The measured temperature of the finished ceiling was only 0.8 degrees below room temperature when the outside temperature was 36 degrees.

Windows and Doors

The Passive House specification suggests that high-performing double-pane windows would be adequate in our area (climate zone 5), however our energy modeling showed that this would not meet our energy efficiency goals. The best double-pane windows have a U of about 0.26 (equivalent to R=3.8), while we found that standard mid-grade Milgard® vinyl windows upgraded to triple pane had a U of 0.18 (equivalent to R=5.5), which was acceptable, so that is what we used in the house (not including the sunroom glazing which is discussed in the Sunroom section). Even with triple glazing, the insides of the windows measured five degrees cooler than room temperature when the outside temperature was 36 degrees.

Unfortunately, our two pairs of glass French doors were not available with triple-glass (probably because those had tempered glass for safety and the weight of three such panes would be prohibitive), so we had to settle for double-glass there, with U=0.27 (equivalent to R=3.7). The inside temperature of these panes measured almost eight degrees below room temperature under the above conditions.

Unfortunately, our two pairs of glass French doors were not available with triple-glass (probably because those had tempered glass for safety and the weight of three such panes would be prohibitive), so we had to settle for double-glass there, with U=0.27 (equivalent to R=3.7). The inside temperature of these panes measured almost eight degrees below room temperature under the above conditions.

Our two solid exterior doors were of insulated fiberglass construction with an R of about 5.

Finally, as noted in Design, we avoided conducted heat loss to the outside from heating ducts by keeping them inside the conditioned house area where any loss stays within the house.

Note: quantifying thermal resistance

In order to have a way to quantify how resistant insulation is to heat flow, the building industry uses two terms. U is a measure of how well something (for instance a window) conducts heat, while R is a measure of how well something resists the flow of heat. They have a simple reciprocal numerical relationship: R is 1/U and U is 1/R. For some reason, R is used for almost everything except for windows and doors which are commonly measured in units of U.

You don’t need to know the technical definitions of R and U for understanding the Demonstration House but, for those interested, the units of U are BTU/hour/ft2/°F, where BTU/hr is the heat flow rate in British Thermal Units per hour. Thus if a window, for instance, had conductivity rating of 1, then 1 BTU/hr of heat energy would flow through every square foot of that window if the temperature difference between inside and outside were one degree Fahrenheit